Embellishment options with flatbed technology

Metallic effects

Haptic effects

Placement of lenses

Combination (Multistroke)

Flatbed technology series RHINO® - Overview and Benefits

-

for short runs

-

for less complex labels

-

for longer runs

-

for complex labels

-

for very long runs / high speed

-

for any kind of complexity

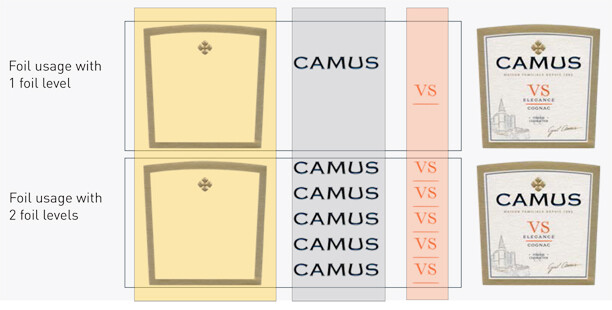

To achieve metallic effects, metal particles are transferred from a carrier film to the packaging. The RHINO® embellishment systems offer up to three foil levels for the most sustainable production. The foils can thus be moved in different steps and used with the maximum efficiency.

Designed for ease of use

An intuitive, user-friendly HMI makes it easy for the operator to run the RHINO®. Its operating system is designed to support daily operation. Features include

-

Process optimized servo control to ease transfer

-

A self adapting register system

-

The possibility to compensate for format deviation within the RHINO®

-

Easy job programming with waste optimization

All these functions help to use the RHINO® efficiently and to save money in every aspect of embellishment.

The RHINO® can be accessed remotely, giving Pantec the opportunity for fast and easy support. Whether there is a technical problem or the need for assistance in setting up the next job, the Pantec support is only just a click away.

RHINO® E 340 / 410

Expand your embellishment capability

RHINO® E is recommended for printers which are either specialized in short production runs or wish to include embellishment capabilities in their portfolio. Beside offering all the advantages of the well-established RHINO® technology, this model is also designed for frequent job changes. In other words, the tools can be changed without cutting the foils. An increasing number of label printers use the RHINO® E in their finishing lines, due to its unrivalled productivity and embellishing quality.

Key data RHINO® E 410/340

-

Up to 18´000 strokes per hour:

-

330 mm substrate advance: 85 m/min

-

250 mm substrate advance: 72 m/min

-

120 mm substrate advance: 60 m/min

-

70 mm substrate advance: 30 m/min

-

-

Multi-stroke with 90° rotatable foil head in web direction or across the web

-

Two foiling levels for optimal foil saving

-

Application of registered foils

RHINO® E can be integrated into any printing machine and finishing line

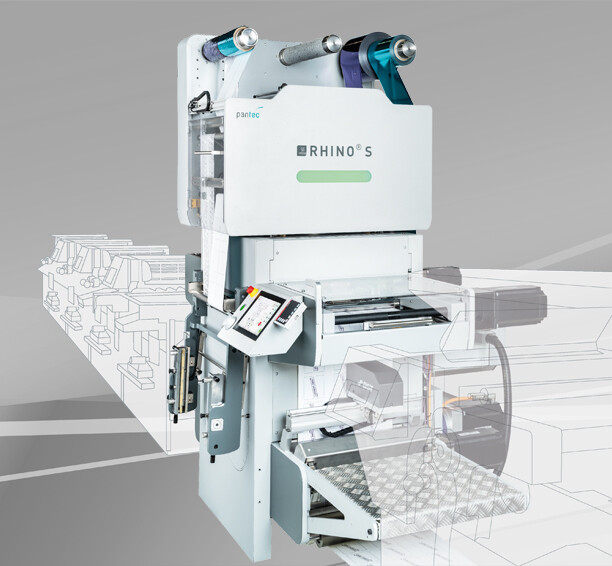

RHINO® S 410/510

Maximize your embellishment productivity

RHINO® S is best suited for label printers who are dedicated to the production of impeccable embellished labels. It combines refined embellishment technologies with a performance that meets the high speed requirements of modern printing machines. With its 30´000 strokes per hour, the machine is fully capable of operating in-line with any modern printing press.

Leading printing companies worldwide rely on the technology offered by the RHINO® S. It enables them to produce cost effectively, outstanding wine and spirits labels.

Key data RHINO® S 410/510

-

Up to 30´000 strokes per hour for high web speed

-

500 mm substrate advance: 150 m/min

-

260 mm substrate advance: 120 m/min

-

200 mm substrate advance: 100 m/min

-

100 mm substrate advance: 50 m/min

-

-

Multi-stroke with 90° rotatable foil head in web direction or across the web

-

Two foiling levels for optimal foil saving

-

Application of registered foils

RHINO® S can be integrated into any printing machine

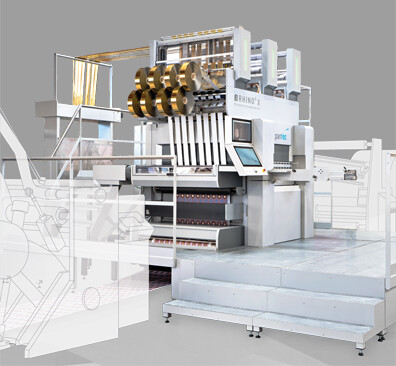

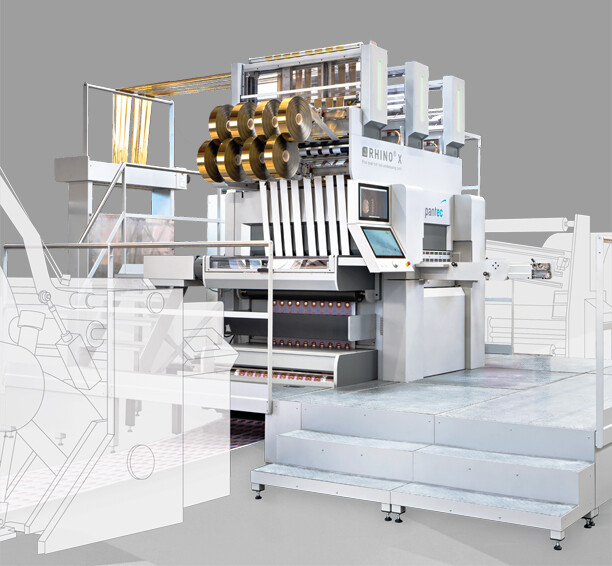

RHINO® X 1060

Surprise your customer with your embellishment capability

RHINO® X brings high quality embellishment and cost-efficient brand protection to the flexible packaging industry. Used as an offline configuration with up to 200 m/min web speed, RHINO® X is a valuable and productive addition to the capabilities of any flexible printing company. RHINO® X is the best option to meet the growing demand by flexible packaging users, who are looking for something special on their packaging to attract the attention of the consumers.

Key data RHINO® X 1060

-

Up to 18‘000 strokes per hour:

-

750 mm substrate advance: 200 m/min

-

500 mm substrate advance: 150 m/min

-

330 mm substrate advance: 100 m/min

-

270 mm substrate advance: 80 m/min

-

-

Multi-stroke with 90° rotatable foil head in web direction or across the web

-

Up to three foiling levels for optimal foil saving

-

Application of registered foils

RHINO® X is usually operated in off-line configuration

Which RHINO® fits best to you? Let´s talk to find out!

René Abächerli

Office: +41 71 5210 821

Mobile: +41 79 500 82 44

Languages:

German

English

Sales Areas

Europe - UK/IRL

USA, Canada

Central Europe - Germany, Austria, Benelux, Scandinavia,

Eastern Europe - Poland, Bulgaria, Hungary, Czech Republic, Slovakia, Serbia, Croatia, Greece

Russia

North-East Asia / Near & Central Asia

Roger Meierhofer

Office: +41 71 5210 840

Mobile: +41 76 420 19 00

Languages:

German, English

French, Italian, Spanish

Sales Areas

Switzerland

Southern Europe - France, Spain, Italy, Portugal

Latin America

Middle East, Africa

India

South-East Asia

Australia, New Zealand